Emulsion Pumps - MiTi Blast

Emulsion Pumps

Multi Torque Industries supplies, installs and services top brand emulsion pumps such as Mono Nov, Napco and Wilden. Working closely with market leading explosives companies, we can now offer a pump to safely and economically handle explosive emulsions and prill while complying to the Australian standards in handling explosives.

We sell to the explosive slurries markets, chemical markets, adhesives market, and petroleum market (transfer, sludges, production).

Multi Torque Industries supply an extensive range of pumps and spare parts at competitive prices.

Mono Nov – Napco – Wilden – ANE

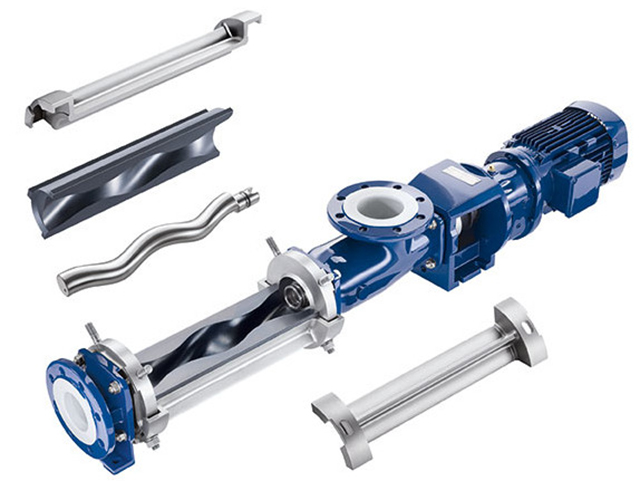

Mono ‘X’ Range Explosive Pumps

The ongoing success of the Mono progressing cavity pump principle has enabled us to supply a pump range, with enhanced design features, specifically aimed at the explosives industry.

For plant and truck mounted applications and existing equipment replacement, the X Range has three separate designs to benefit the following applications:

- High solids content

- Surface transfer

- Existing equipment retrofit

Advantages

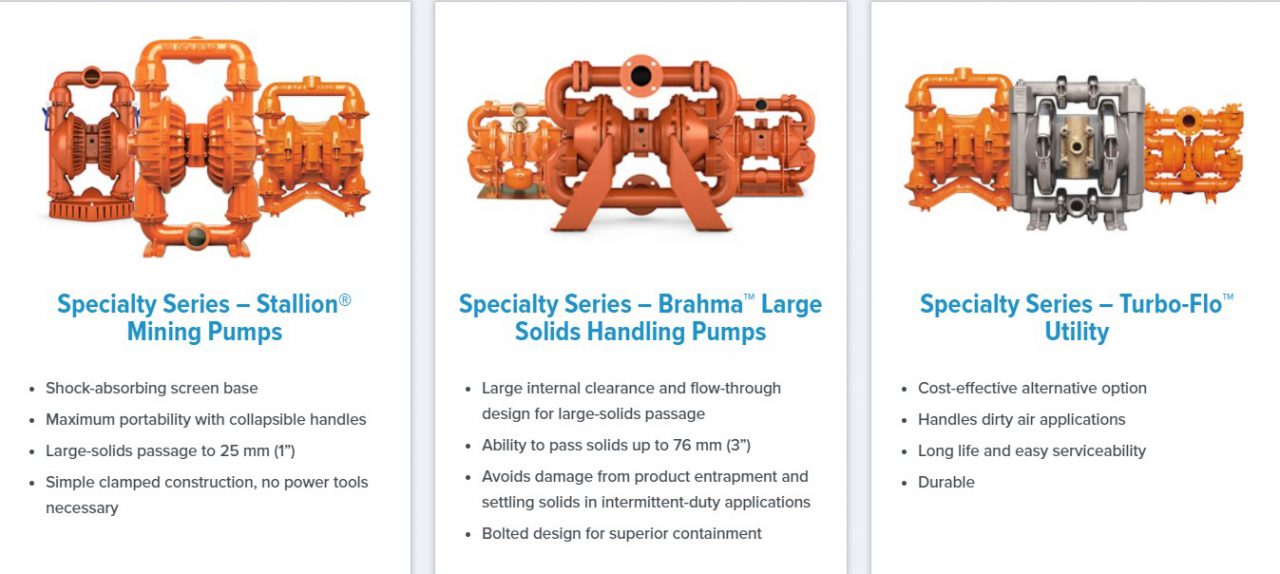

Wilden Specialty Series Pumps

We supply, service and maintain as well as stock, parts for Wilden pumps which are the ideal solution for a wide variety of mining applications because they possess the design and materials of construction needed to handle the harsh conditions. Wilden Air-Operated Pumps offer considerable operational advantages, like comparable low-speed operation, dry-run, line-stripping, self priming and deadhead capability, along with increased operational safety and a reduction in maintenance/repair costs that can be incurred by pumps that are not designed to handle abrasive/corrosive or solid-laden liquids.

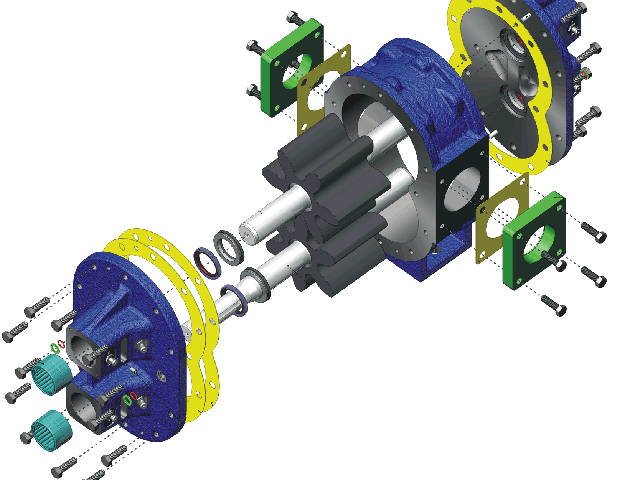

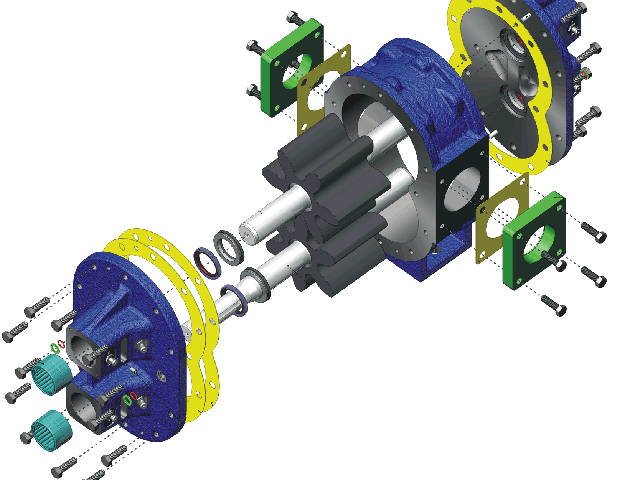

NAPCO Rotary Gear Pumps

The NAPCO rotary gear pump is available in 316 stainless steel and ductile iron, and can handle a broad range of pumping applications from water to highly viscous or abrasive fluids. It can also handle some corrosive fluids. It comes fully lubricated and ready for use. It operates clockwise or counter-clockwise with equal efficiency. The rotary gears come standard in high temperature nitrile rubber, but neoprene, Viton and other gear material can be ordered to handle special higher temperature or corrosive fluid applications.

NAPCO rotary gear pumps are positive displacement pumps. As the rotary impeller turns, the gear teeth open, creating an expanding cavity on the inlet side to vacuum fluid into the pump chamber. The impellers carry the product around the pump cavity to the outlet side and, upon meshing on the outlet side, force the fluid out of the pump.